About Warehouse Management System - MSF WMS

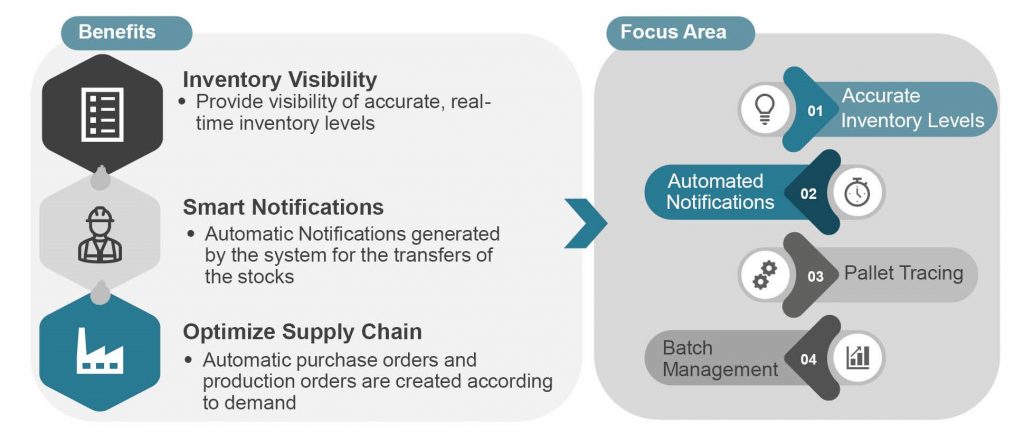

MSF Smart Warehouse Management and Inventory System (WMS) provides manufacturers with transparency about the status, location, and quantity of materials at all stages from purchasing to production. It is possible to carry out these operations but to monitor all processes instantly, by digitizing all material flows.

In addition, since this digitalization process is directly related to other production functions and especially the material transfers of the planning processes and their readiness for production, it becomes very important to monitor the instant material status.

This material flow process, depending on the operations in the production tree, also requires consistency in the amount of material entering the production and the product output, to monitor complex processes such as transporting semi-finished materials to the relevant station or transferring them between warehouses, transporting scrap and rework materials between several production stations, depending on the operations in the production tree. Materials and processes in production both need to be well integrated.

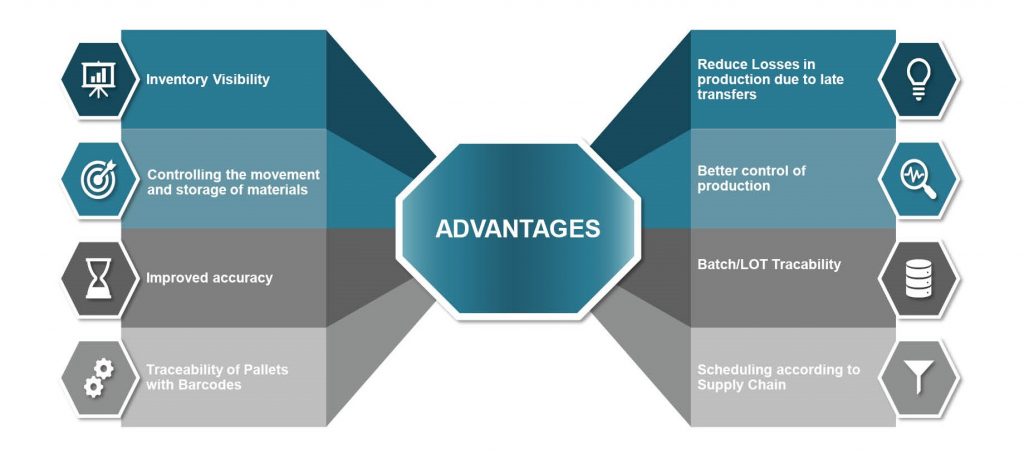

In order to meet this need, MSF software can easily make a transparency of all materials and their production visibility at the level of warehouses and workstations. MSF Smart storage is enabled by a variety of automated and interconnected technologies. These technologies work together to increase the productivity and efficiency of the warehouse, minimizing human headcount while reducing errors.

.

Most of the time, warehouse workers can be seen collecting the products, loading them on the trolleys, and then delivering them, while they are counting the consistency/inconsistency of the lists or the numbers in these lists over and over, but in MSF smart warehouse management, since the production order is related to the purchase, the orders go from purchasing to product delivery.

The system directs the transfers of materials directly to the transportation processes with notifications without the need for physical counting.

In the MSF Smart Warehouse system, a fast and accurate result is obtained by working together with various interconnected algorithms. It does this with a technological ecosystem where materials are automatically shipped. Thus, the MSF smart warehouse solution automates almost the entire operation, from the purchase to the sales customer, with minimal error.

MSF Smart Warehouse monitors all movements from planning to production of materials needed to purchase materials in the master of materials or to produce in the workshop, notifies them to be placed in special warehouses, reserves them to work orders, transfers them on time, and has agile, scalable and data visibility capabilities.

Working together with the machine-to-work process, sales systems, and other storage functions, it can collect faulty production and good parts in pallets and collect them in designated warehouses. Each material can be accurately monitored with different algorithmic methods for post-production and a possible quality requirement.

MSF gives transparency and planning safely by way of real-time tracking of materials through the entire flow chain in production. It can observe material buffers in operations, so forecast stock level for procurement, real-time updating production, and material can be easily seen on the screen with Bach, so it can be optimized for transportation or forklift trips.

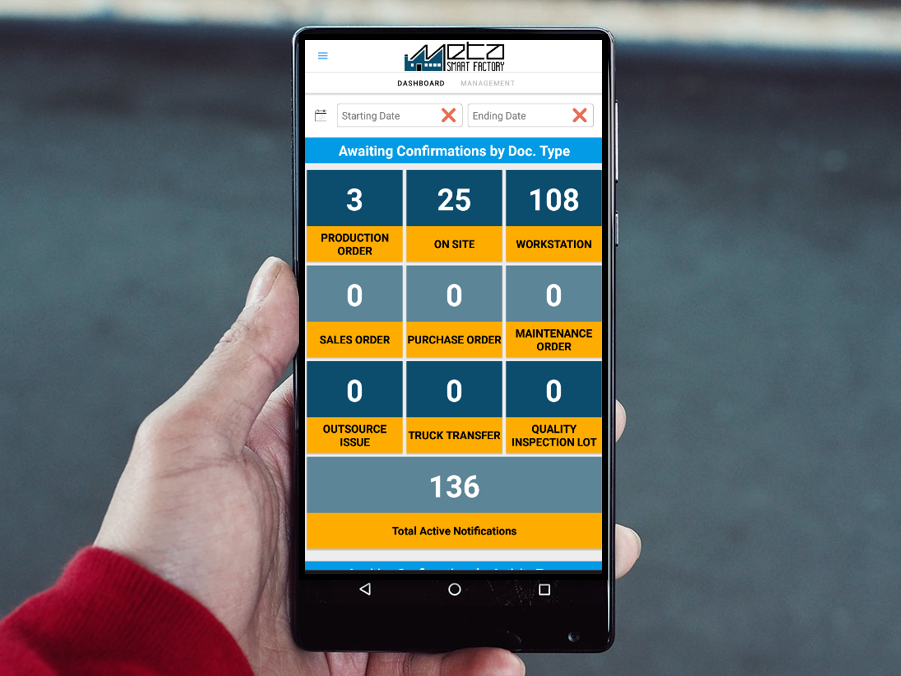

Mobile phone tracking

MSF android application can be used to provide instant notification notifications to the operators in warehouse transfers. When the application is used, the realization and approval of the transfers are instantly updated to show the latest status of the material movements.

This application was developed by MSF with user-friendliness and simplicity. At the same time, it can be installed on any android mobile phone, eliminating the need for expensive hardware and software.