Meta Smart Factory Products

Intelligent Supply Chain Planning (SCP)

Unlike common EPRs, MSF Advanced SCP is fully proactive system that connects and plans all levels of departments together, from Sales and Purchase to Production and end delivery.

Advanced Planning & Scheduling System (APS)

This process flow simulation software can automatically plan production & adapt to changes in real-time according to scenarios that are happening in shop floor.

Smart Labor Scheduling & Management

For the last stage of complete production mngmt, MSF Labor Scheduling plans employees or groups dynamically and flexibly in real-time. Can integrating with other systems, MES…

Advanced Manufacturing Execution System (MES)

Shop floor digitalization or MSF MES has the potential to be fully integrated into any production. Digitalizing new/old workstations, labour and manual jobs, IoT, Sensors… Professional solution for any production shop floor.

Advanced Maintenance Management

Maitenance management can fully trace and create maintenance orders, tasks, plans, reports. Inside predictive and preventive maitenance, combining with MES can fully supervise everything mtnc related: personnel, notifications, equipment…

Smart Warehouse Management System

MSF Smart Warehouse System manages all stocks and future stocks, works in real-time with APS and MES. MSF Smart WMS gives manufacturers full real-time transparency and visual overview, plus it works with Logistics and Auto-Dispatching.

Advanced Quality Management

MSF Quality Control Management, real-time visibility into quality, no manual entering of data, full traceability if connected to MES, inspection plans and scenarios, ISO standards compatible with customizing capabilities.

Business Intelligence (BI) and Analytics KPI

Access to full reporting system from quality related to business focused reports to help you with the production related decisions. BI also provides valuable insights and analytics for management. The best module for business overview and cost orientated strategies.

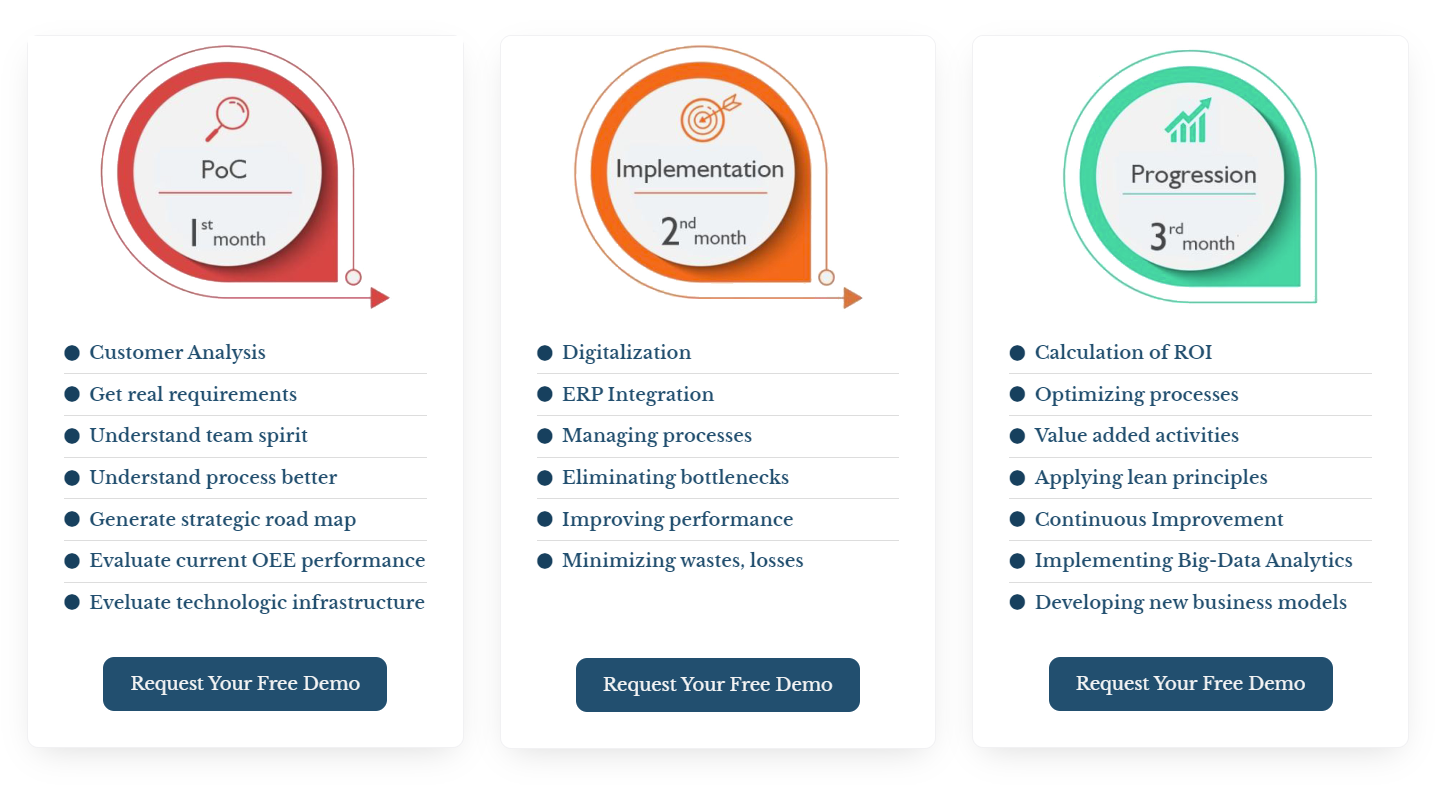

How to make your factory get better with MSF Solutions in 3-6 months?

MSF is a plugin solution that digitalises all your processes and creates full Industry 4.0 company. Choose from many independently working modules: MES, SCP, APS, WMS, Logistics, Quality, Maintenance, BI…

Implement all plant settings - run simulations of your current and future plan and decide which route to take.

Connection of all assets in a production environment to gather as much information as possible in real-time.

When good data is generated, advanced reports are available and can be created automatically. Creation of customized reports.

How does Meta Smart Factory work?

Working with MSF you’ll get full scope of knowledge and experiences from IT and Industry. During PoC we’ll work on your requirements, after we prove to you system is working, we start with project. You can decide which module you’d like to use, MSF will offer full VIP support and consultancy during project. But remember, success and speed of the project comes mainly from your side.

During project, MSF targets increasing productivity, increasing supply chain profitability, improving quality, lowering costs, decreasing delivery times, improving employee satisfaction/morale, and reducing employee turnover rate by implementing a continuous improvement environment.

APS Frequently Questions

Advanced Planning and Scheduling (APS) is a digital solution that helps manufacturers to manage production planning and shop floor scheduling. Using advanced algorithms to balance demand and capacity and generate achievable production schedules, Advanced Planning and Scheduling (APS) function results in shorter delivery times to meet customer demands and easier, more rapid response to unexpected production changes.

APS helps manufacturers forecast their production resource needs; It paves the way for higher profits by regulating the efficient use of materials, people, and machinery, and by planning options that will deliver faster delivery to customers. With MSF APS, you can have long-term planning covering months or can be used for one or several weeks of planning and detailed sequencing and scheduling.

MSF APS can be used not only as a standalone system for planning and scheduling, and but also be used and integrated easily with Enterprise Resource Planning (ERP), Manufacturing Execution System (MES), and other software solutions.

For planners, APS systems quickly analyze the iFor planners, MSF APS quickly analyzes the consequences of alternative decisions, visually highlights consequences and problems, and creates optimal or near-optimal plans and schedules.

MSF APS provides planners and managers with the best information and recommendations to combine all capabilities and capabilities to form the basis for their decisions. As such, it is an important tool to assist in managing complexity. While large numbers of items, orders, machines, and workers move quickly together, it is difficult to plan effectively with their complex constraints. In such environments, MSF APS can offer optimal planning and scheduling.

APS creates a type of computational optimization using many mathematical algorithms. In manufacturing, APS establishes a method for simultaneous synchronization of material and capacity with customer orders. APS prepares the plan and schedule for the execution of the production processes, then transfers it to ERP to manage the execution of the plan or schedule. APS can also be used as part of stand-alone systems or system suites, especially in larger organizations, if data interfaces are integrated. Many APS tools and techniques can be used in supply chain planning. This includes multi-purpose functions such as purchasing management and sales forecasting, factory planning and scheduling, inventory planning, transportation planning, product lifecycle management, and inter-institutional and intra-organizational coordination.

APS planning functionality considers forecast and long-term orders, supports decision-making about the feasibility and affects the general direction of production operations. APS supports decisions surrounding extending the workforce, resource capacity, and factories. It helps manufacturers determine what and how much to make, where and when to make it, and exactly what resources are required.

Planning can be executed in planning periods can be days, weeks, months, or a combination of all three.

Advanced Scheduling functionality considers the availability of resources and additional constraints, such as tooling and materials to ensure an accurate model of the manufacturing environment. Advanced Scheduling schedules orders using intelligent built-in rules. It provides decision-making support for overtime, order prioritization, due date negotiation, and order processing.

APS oversees numerous aspects of a production environment, including:

Master Production Schedule creation

Bill of Materials (BOM) level planning

Interactive schedule visualization

Make-to-order planning

Make-to-stock planning

Advanced constraint modeling

Advanced material handling

Advance schedule optimization

Assembly process visualization

Interactive schedule viewing

Order-based multi-constraint scheduling.

When production demands, production queues, and anticipated changes in production are required, advanced planning and scheduling solutions are used by managers to better improve their decision-making processes. APS software helps make changes or see what impact changes in scheduling will have on production, creating real-time production efficiency in the factory.

When machine failures occur or parts are scrapped in production, advanced scheduling helps support contingency scenarios such as:

“What is the cost of accepting an urgent order?”

“Will prioritizing a new urgent order hurt our completion time for other pending orders?”

“Can we afford to pay our employees overtime to complete this job?”

“When can we move a machine into a maintenance stage without slowing down production?”

APS will help you see the true impact of each scenario. Managers will be able to provide their decisions with a dashboard or KPIs that can help visually demonstrate the impact.

By improving the synchronization of production processes, APS provides visibility into more options to increase production and on-time delivery while reducing inventory levels and waste. Advanced artificial intelligence algorithms, it enables manufacturers to quickly analyze and calculate achievable production schedules, taking into account multiple constraints and business rules. So planners can create and evaluate case scenarios to achieve the best results.

Additional benefits:

Late deliveries due to manufacturing delays

Missed sales due to demand exceeding capacity

Lost orders due to excessive work-in-process

High production costs due to machine ineffectiveness (such as downtime)

Excessive overhead due to managing scheduling changes and the impact on delivery schedule

Difficult to plan for future capacity requirements

Full visibility and control

Increased utilization and leaner operations

Faster response to change

Better customer service Higher margins

The biggest difference between production scheduling software and advanced planning and scheduling software is in the name. Both options may provide nearly similar functionality but may be marketed under different terms.

In other words, the software can be called production planning software or advanced production planning software. In fact, it can be said that production scheduling is just one of many features available in APS software; this means that the APS software is an enhanced version of the production scheduling software.

In essence, both production planning software and APS software are capable of scheduling many orders that need to be processed according to specific processes and specific product routes. Both systems can create a program that can be viewed in a variety of ways but is typically seen as a GANTT chart. These charts show how ordering products will take place in different processes.

In most cases, the user can change the production plans and try various scenarios to play with different situations on the production floor. If desired, in addition to calculating material consumption, APS can prevent scheduling of production orders after any material is exhausted and automatically generate supply orders when any material is partially finished.