Overall Equipment Effectiveness (OEE)

Productivity in the factory is very much related to the maximum utilization of machine capacity. Factories need to see how any machine efficiently runs without hidden capacity. MSF OEE can help the need to measure both to do things right and to right things.

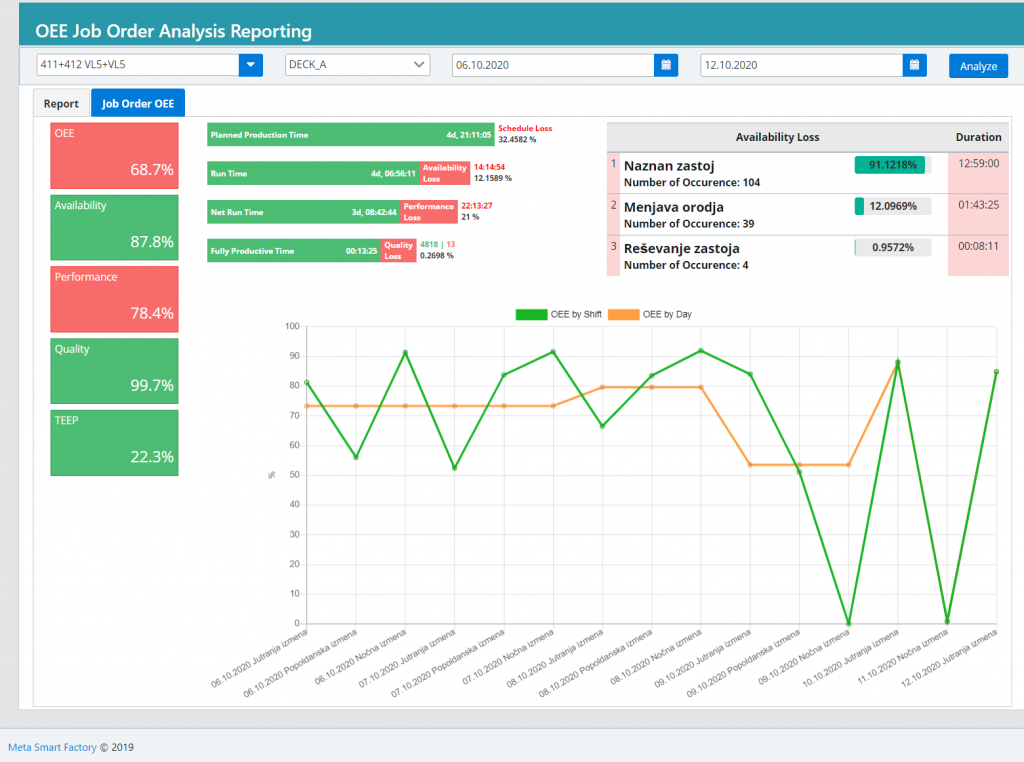

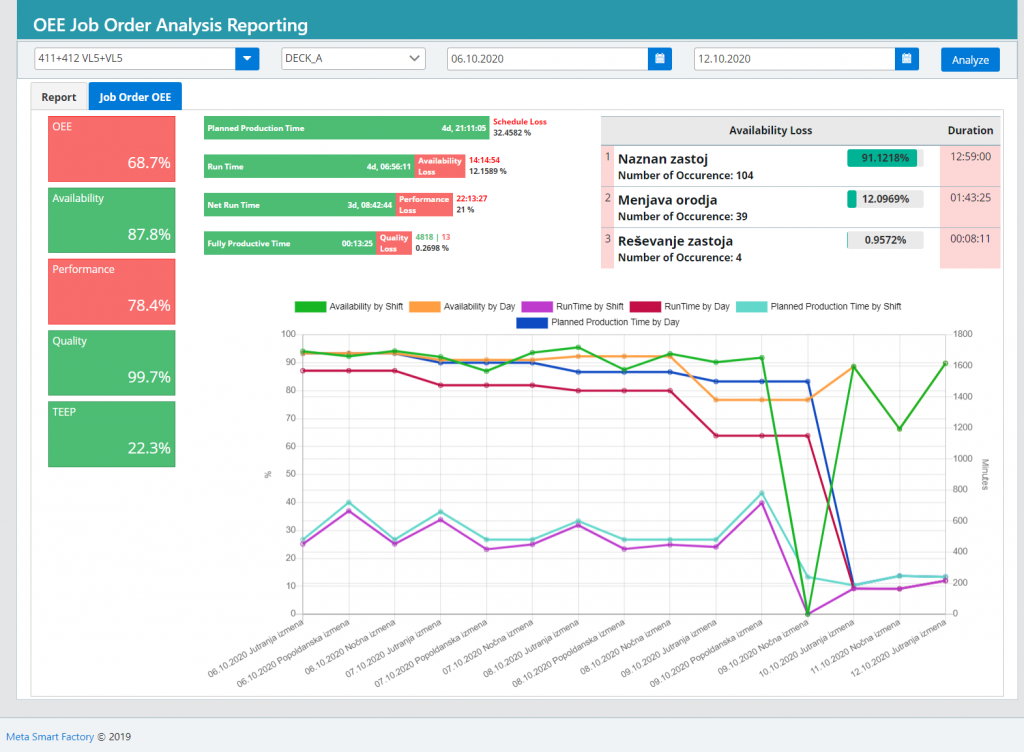

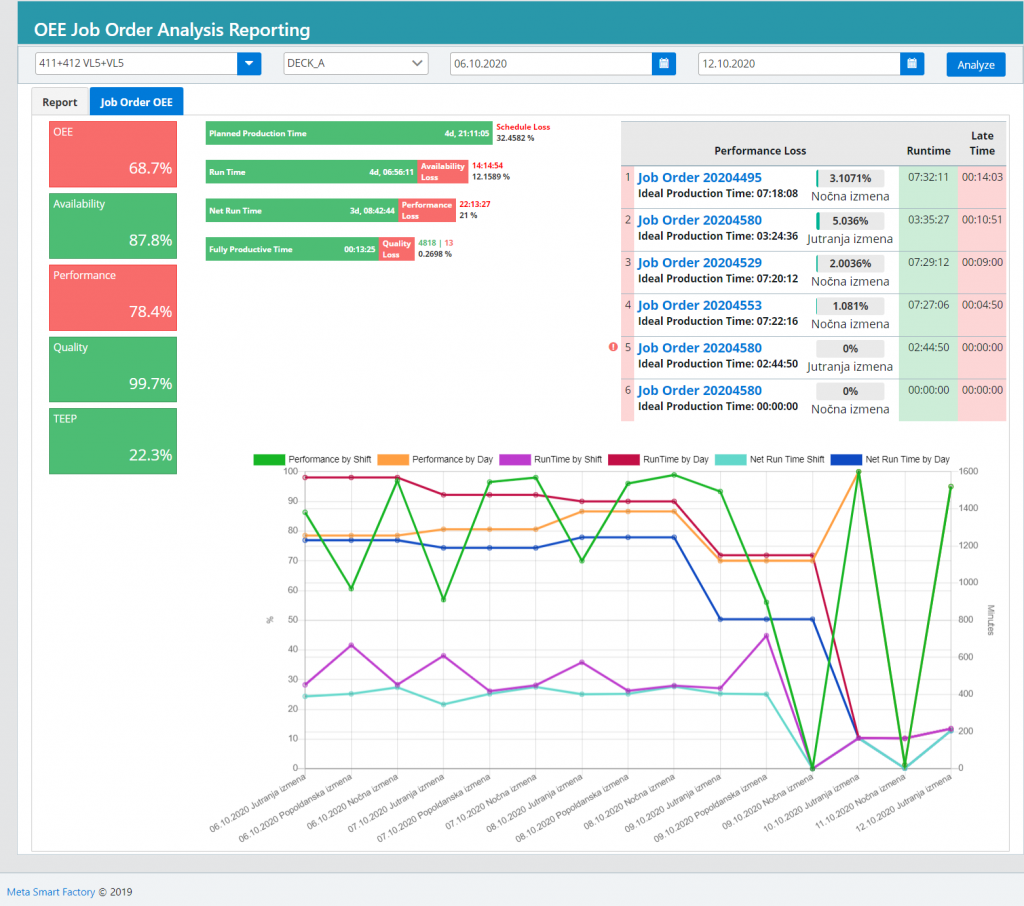

Efficient operation of individual production equipment parts, assembly lines, or the entire factory depends on OEE factors. These are possible, starting from planning, by measuring availability, performance, and quality. OEE is calculated below basic factors and shows results on the MSF web application.

MSF provides;

MSF measures machine downtimes together with real-time reasons, and shows OEE to factory managers in the specified period or live. The obtained capacity information helps managers to make the right production planning, taking into account the factory capacity during planning.

Automating your production reports with MSF is a significant OEE calculation benefits with:

- Save time and save money.

- Get data real-time that factory hasn’t have before.

- Increase the reliability and accuracy of factory reports.

- Visualize production data in an easy-to-understand graphics.

- Utilize the potential of employees by freeing up their time.

MSF OEE real-time focuses the plant on the concept of zero breakdowns and zero scraps. Unless careful monitoring occurs, the reduced capacity in the plant goes unnoticed or is accepted as normal. MSF OEE combines the operation, maintenance, and management of manufacturing equipment and resources.

MSF uses a unique smart I/O device to collect all relevant information from production by utilizing sensors, PLC outputs, or others. MSF then securely stores the data on the cloud, so that the factory can access it from anywhere and anytime which automated and real-time production monitoring enhances productivity and efficiency. With the right tools, MSF production monitoring provides the potential to transform an entire manufacturing company. Therefore MSF helps reduce costs, find opportunities for improvement, and aids in the achievement of goals.

No longer any employee needs to enter the collected data into Excel, which saves the factory workforce countless hours of work time that it can be used more productively. More importantly, you free your people from the burden of manual data collection and let them do value-added tasks. Furthermore, it means you don’t have to worry about the accuracy of data anymore.

MSF reports give an essential way of understanding the effectiveness of the production process and the impact the factory efforts have on improving the process. The factory can be kept track of its OEE, downtime, performance, quality, and a lot more.

All this data can quickly become available without burden for any manager. Having to track, aggregate, put together, and present different KPIs, each week and month, manually, really is a waste of time without MSF OEE report capability.

Results

A customer who started using the MSF OEE module for about a year wanted to measure and improve the efficiency of their factory. During this time, it increased its OEE by an average of 20 points and machine downtimes decreased to 20%.

MSF provides detailed, accurate, timely, and precise production data that can be driven to change across all roles and responsibilities.

By using MSF, operators can focus on what they can improve in the next few hours. Production Line can be accelerated. It can be reacted quickly to disruptions in production by the managers. He can use shifts to be proactive, not reactive. Also, managers can focus their time on making improvements to increase not only daily work but long-term production rather than daily work. Can analyze the structural problem areas in production.