Meta Smart Factory Advanced

Real-Time Modules

MSF PRODUCTION PLANNING MODULE

MSF Manufacturing Execution System (MES)

MSF has Manufacturing Execution System (MES) solution for enterprises that is a fully integrated and helps to collect and analyze all shop floor production data like machine, employee, material, quality management and other process in real time.

MSF MES helps to enterprise to make machines, materials and products “smart” and connected for having the ability of Industry 4.0, Smart Manufacturing and Digitalization their production process.

MSF MES can be used such in automotive, plastics, metals, electronics, steel, packaging as well as chemical, food and beverage industries.

The functionality of MSF includes shop floor basic and advanced scheduling, machine and order data, material and production, goods movement management. MSF provides employee related data time and attendance for personnel scheduling. Quality management function collects data starting from receiving material to in production inspection like scrap or rework with causes. MSF makes all shop floor data to produce analytic KPI reports which are shown on MSF Report & Analysis module. Collected data is shown not only as KPI report as visualization of data, but also alerts and notifications, integration to their enterprise systems, forms, dashboards, collaboration and data analytics.

MSF can be easily integrated all ERPs in industry and all kind of shop floor equipment. Beneficial of this integration capability makes any enterprises easy to integrate shop floor level management system, with this MSFs modular structure provides flow information seamless in real time and at the end MSF gives powerful functions for production environment.

Enterprises with MSF MES can trace and monitor all production orders with their operations in real time that can be transferred orders from its like ERP system, generate production orders, split orders or operations, log in/out employee, configurable panel dialogs easy to collect data and support Kanban systems.

MSF MES acts as a master layer from the bottom-up, meaning from the equipment interfaces and IoT to the layers above. MSF MES collects along the production cycle of bringing the detailed data to the cloud. Then MSF MES acts more strategically to top-down with computed data. It means that data comes from the shop-floor processes that determine whether the company makes a profit or not. MSF MES orchestrates the lower-level equipment and devices in alignment with these value-adding processes. Since the ultimate goal of MSF is to guarantee productivity increases, this occurs through processes. Thus, manufacturers achieve consistent quality of products through quality of processes and quick introduction of new products through efficient processes across departments.

MSF Advanced Planning System (APS)

MSF Advanced Planning System (APS) consists of three functions: Real Time Production Monitoring, Production Auto Schedule and Labor Auto Schedule Functions.

Production environment on shop floor, it can be observed production changes in real time like machine status and material details. MSF real time monitoring shows all production that can be monitored by way of dynamic real-time systems that collect and process the complete range of production-related data such as quantities, process parameters, and plant and machine status.

MSF auto schedule functions in case of unacceptable deviations or discrepancies, corrective steps which may include MSF input, are automatically executed. Depending on the degree of automation, data can be directly transferred to subordinate systems.

MSF production auto scheduling optimizes machine utilization, provides computer-based rescheduling due in case of changes in priority or others, and clearly displays the process execution. Thus, it ensures on-time and optimized production runs.

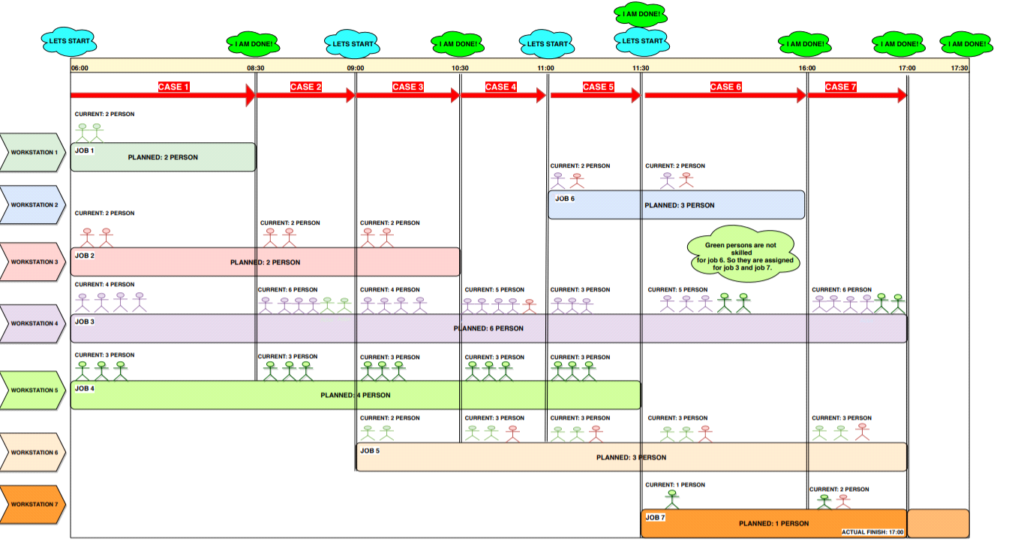

The solution is that MSF provides managing the employee dynamically and flexibly in real-time using hidden capacity. In addition to this, it can be assigning job orders to workstations optimally and planning instant production status changing.

MSF labor auto schedule is a process the operation data which is transferred to the system and artificial intelligence algorithm decides the number of people to be assigned to the relevant operation. While the algorithm is deciding the number of employees for the related jobs, it uses before stated total capacities in the system, thus the job orders automatically plan to reach maximum capacity every hour. Also, employee abilities are considered when employee is selected for the related job.

MSF manages the production areas properly with an exact production auto scheduling, thus provides to increase production efficiency and flexibility, saving time spent on planning, increasing the production capacity, line balancing and revealing hidden capacity. On the other hand, as employee management is kept under control with real-time labor auto scheduling, workload balancing is provided.

MSF Material Requirement Plan (MRP) System

MSF Material Requirement Plan (MRP) is a part of production order which has a list of the raw materials or components, quantities, time, and steps required to manage the production or assembly of finished goods.

When the planners plan the product to be produced, if the raw materials to be used are only procured and the production will be carried out, an appropriate MRP is created. However, sometimes the products to be produced are included in the MRP plan, the materials to be produced and become components, and the purchased raw materials are included in the MRP.

The shortest lead time to be created in the planning and the most optimal “routing” planning that will not create a bottleneck in the inclusion of the components to be produced in the “parent” product is the problem that planners should cope with.

MSF MRP helps to process a production order with sales order by turning various components or raw materials into a finished product by making use of machinery and labor. Also, MSF MRP allows enterprise to group individual sales items in stock to sell a ‘parent’ product composed of multiple components which are then issued from the inventory once the order is dispatched. These are for a fixed combination of items, but you’d use a sales order if the customer needs confirmation of each component or wants to alter quantities. MSF manufacturing planning module functions to creates a list of items brought together for sale at the same time and gives you the flexibility to change the quantities, swap and delete items to customize a sales order.

Once MSF MRP is done the purchase orders and production orders are created which will trigger the procurement cycle for the new components. Meanwhile the components are being procured the planner works on the shop floor routing details with the reference of MRP. Once the Purchased components have been procured then the Manufacturing Execution can be started. So, the Activities mentioned in the Shop Floor Routing is performed and the Product is built.

MSF also keeps material in reservation dedicated the respective job if stock quantity available. Or based on reorder planning, material purchase or making component function executes automatically, if quantity drops below minimum amount.

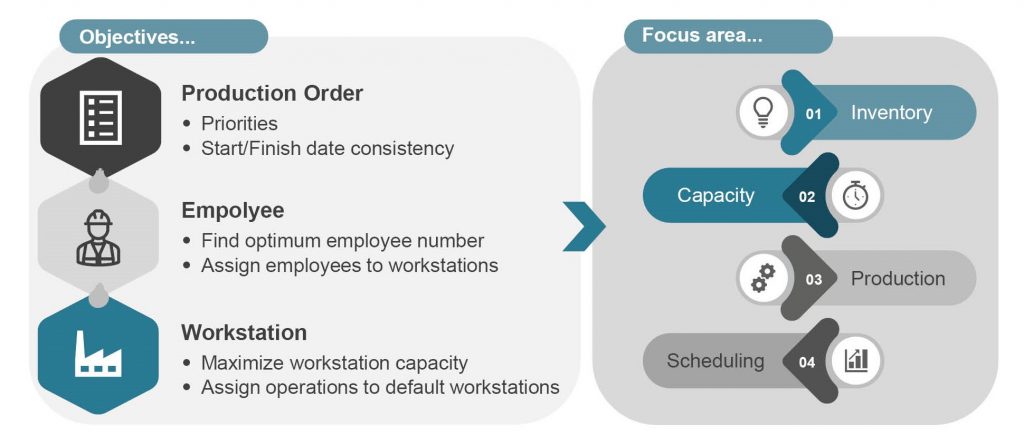

MSF PRODUCTION AUTO SCHEDULING MODULE

MSF Scheduling is starting with Production planning that ensures enterprises have sufficient raw materials, labor and resources in order to produce finished products to schedule. It is a crucial step in production management and scheduling.

Secondly, routing of manufacturing process that MSF MRP defines the path from raw materials through to the production of a finished product. If done correctly enterprise will know at what stage its item is at and which machine, tool, or work center it needs to travel to next.

Then production scheduling can apply the management of these processes to make sure they are completed in a timely and efficient way.

Lastly Execution related to the process of undertaking the production plan. Having already established its production planning, routing and scheduling, the execution stage is when you issue supporting orders or instructions in order to enable production.

MSF scheduling has capable of prioritize orders, employees tasks get shifted. MSF calculates the completion time based on other processes such as machining. With MSF, the system does not wait around to tell the staff to start a new order. If the first order is still being machined, MSF will allocate team members to tasks further down the list.

The team can use MSF to work out when they can shift back to the first item on the list. MSF assigns the most logical tasks for your team to do to create harmony on the shop floor. There is no idle time for smart manufacturers. You can plan your whole manufacturing production schedule in the most efficient way possible.

As the team completes their tasks, they can be checked off the list. MSF scheduling page shows several completed tasks, clearly identified by the scheduling page.

MSF Scheduling utilizes production scheduling to help enterprises manufacturing facility plan, route, schedule, dispatch, and execute the production schedule. These can provide oversight thorough insight within the manufacturing operation.

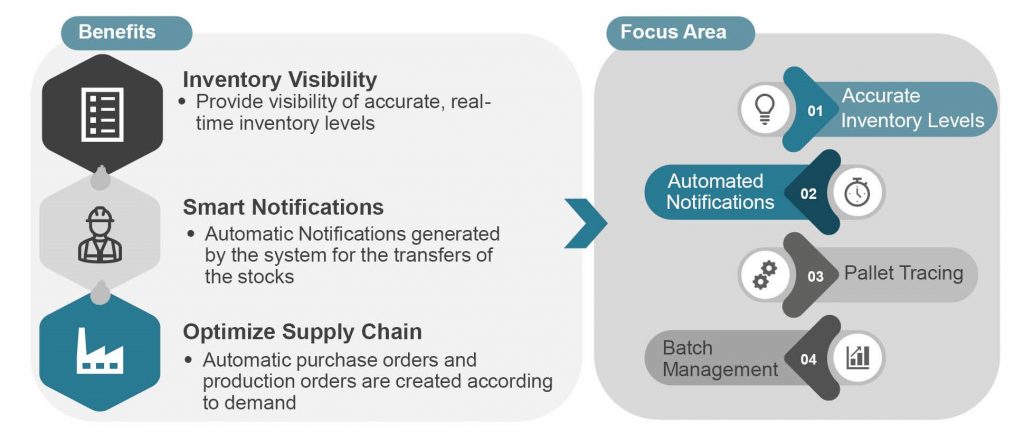

MSF INVENTORY MANAGEMENT MODULE

MSF Smart Warehouse Inventory Management gives manufacturers transparency in material and manufacturing together. Processes in material and production both need to be well integrated. MSF can do all these material and manufacturing transparency needs. MSF Smart warehousing is enabled with several automated and interconnected technologies. These technologies work together to increase the productivity and efficiency of the warehouse, minimizing the number of human workers while decreasing errors.

In manual warehouses, employees can be seen walking around with lists, picking products, loading them into carts and then delivering them, but in MSF smart warehousing, orders are received automatically, after which the system confirms if the products are in stock. The pick-up lists are then sent to forklift that place the ordered products to deliver them to workers for the next step.

MSF Smart Warehouse system is the result of the various interconnected technologies working together. They form a technological ecosystem where goods are received and shipment automatically. MSF smart warehouse solution automates almost the entire operation, from purchasing to sale customers, with minimal errors.

MSF Smart Warehouse has agile, scalability and data visibility capability of overseeing all movement of material from planning to production which are needed to buy or make in shop floor, make notification to put in dedicated warehouses, to reserve to job order, transfers in time to machine to job process, then, can collect good parts in pallets or scraps to certain warehouses after production, thanks to work with sales systems and other warehousing functionalities.

MSF gives transparency and planning safely by way of real-time tracking of materials through the entire flow chain in production. It can observe material buffers in operations, so forecast stock level for procurement, real-time updating production and material can be easily seen on the screen with Bach, so it can be optimized for transportation or forklift trips.

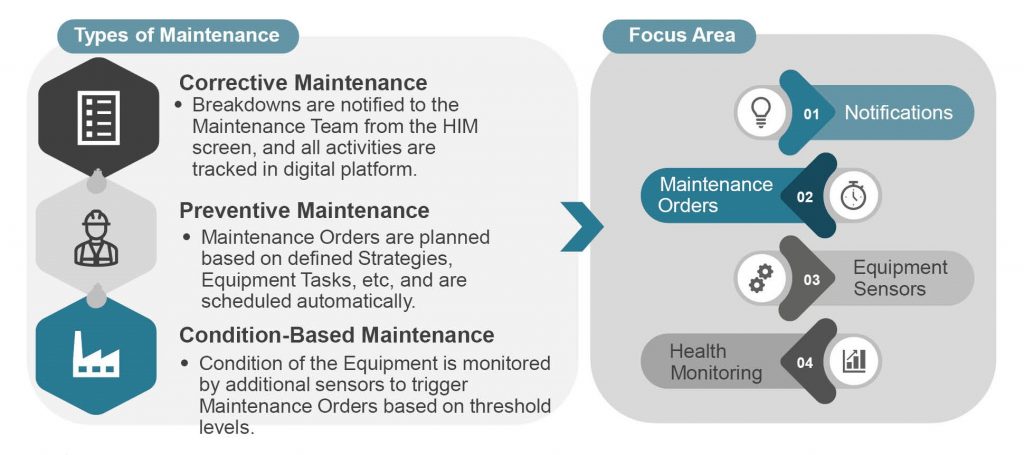

MSF MAINTENANCE MODULE

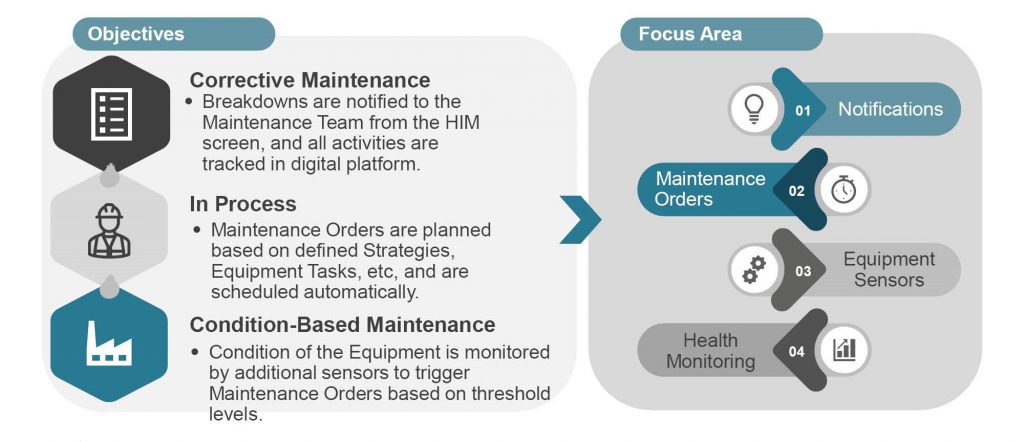

MSF Maintenance System module is designed to manage and provide a single interface to production operations with maintenance management functions. MSF gathers the shop floor information about the use of machines data providing use of the maintenance process. This information on the causes of machine stops are used to optimize the planning of maintenance activities and make it as compatible as possible with production activities.

When the machine stops for break down for maintenance, MSF maintenance module is designed to notify machine status to planners or managers by making use of maintenance notifications by operators. At the same time, having all this information related to scheduled maintenance, MSF is enabling them to take appropriate action to minimize the impact on scheduled maintenance planning activities.

MSF Maintenance System Module consists of key activities to include corrective, preventive and predictive maintenance using some measurement points in order for maintaining machines healthy.

MSF Maintenance System Module performs these activities based on equipment master record details via management, to make plan of maintenance tasks, use workflow notifications and work orders under maintenance order management.

MSF maintenance functions links to other modules starting from steps; notification, creation work order, creation of purchase request for work orders, after purchasing and parts receiving parts issues to Work Orders, approving of planned Work Order, scheduling and releasing Work Order, Work Order Execution and Closing a Work Order.

As a result of these processes, MSF ensures the health of the machines in order for improving machine uptime with proactive or predictive maintenance planning and scheduling, reducing total cost of ownership by avoiding machine breakdowns, enhancing safety and environmental compliance through integrated permit and working clearance.

MSF Maintenance System Module gives also maintenance activity reports like Mean Time to Repair (MTTR) and Mean Time Between Failure (MTBF) that shows analysed giving dates maintenance performance on each machine and maintenance group.

MSF MTTR can help you start investigating the root cause of failures and get you on your way to a solution. On the other hand, MSF MTBF reports is a prediction of the time between the innate failures of a piece of machinery during normal operating hours or how long a piece of equipment operates without interruption. MTBF analysis helps maintenance departments strategize on how to reduce the time between failures and together, MTBF and MTTR determine uptime.

MSF QUALITY MANAGEMENT MODULE

Best quality systems will help manufacturers comply with all health and safety guidelines in the workplace and thus avoid big fines and other penalties that can result from non-compliance. To this end, the right manufacturing quality application is able to collect all applicable data from integrated systems to monitor workplace safety and to prevent any potential workplace hazards. Right solution also facilitates generation of reports. The system should also enable manufacturers to design their own testing procedures of incoming materials to make sure that they meet all the requirements, starting with the quality of raw materials and spreading throughout the entire manufacturing process.

Added values to the enterprise with MSF QM are reducing scrap, waste, warranty claims and rework, having record every single defect and enabling full traceability. And also, MSF QM ensures, having elimination of papers, supporting business improvement initiatives to realize the right first time, having improved product quality through reports/analysis and in terms of reducing cost of critical quality issues.

By integrating Quality functions into MSF, enterprises have real time visibility into quality and eliminate the time entering redundant data and logging in-and-out of disparate systems.

When an operator/technician on the shop floor encounters a discrepancy, they are able to initiate the non-conformance within the electronic work instruction, simply by stating what happened or what went wrong within the same single glass view on the shop floor, without having to log in-and-out of multiple systems or enter redundant data that is already noted in MSF MES.

And from there, corrective actions can be created and executed in real-time. The ability to have these corrective action functions within MSF is especially beneficial in complex discrete manufacturing environments where unplanned events, discrepancies and engineering changes can and do occur often. MSF with integrated Quality functions not only saves everyone’s time, but also promotes a Proactive versus Reactive quality environment, that can actually drive down your cost of quality. MSF Quality module has functions also in the existing supply chain by connecting to materials management, production planning, warehouse management, and other logistics processes.

MSF Quality module ensures materials in warehouses via inspecting incoming material as it arrives at the facility and in manufacturing operations, where the quality of in-process items is checked during the manufacturing process and finished goods are inspected before they reach the warehouse.

MSF quality module provides also advanced quality control function that is a structured process aimed at ensuring customer satisfaction with new products or processes. Quality control setting in MSF has different parameters which can be put in base on the factory engineering needs. During the production in process, MSF collects all quality data includes scrap and rework with their causes. Then it can be taking an action to reduce scrap or rework. Thus, MSF gives good opportunities to make better quality product for customer satisfaction.

MSF LABOR MANAGEMENT MODULE

MSF Labor Management module supports manufacturing excellence by tightly linking labor tracking to plant activities, not only production, but also warehouse, maintenance and quality in manufacturing environment.

Synchronizing labor with manufacturing provides a powerful view of your workforce and how it affects your critical plant operations, activities in productivity.

MSF Labor Management collects data throughout your manufacturing operations in real-time. This data utilizes to integrate time and labor across all operations, enforce company pay and work rules, reduce labor and administrative costs.

It gives opportunity to automate the tracking and management of time and labor processes in the context of production to enhance productivity by eliminating manual processes and validating time accuracy.

MSF labor management is linking specific labor activities to production metrics for improved analytics capabilities to better understand performance against planned. It is providing real-time visibility of employee attendance and availability, for improved responsiveness to daily manufacturing needs, automating and simplifying the production of reports for other systems and capturing labor information as part of traceability and genealogy requirements.

MSF labor management also help to labor auto schedule which is a process in the operation using artificial intelligence algorithm decides labor to be assigned to the relevant operation. While the algorithm is deciding quantity of labor for the related jobs, it uses total capacities in the system, thus the job orders automatically plan to reach maximum capacity.