Automotive Industry

Metalworking Industry

MSF collects all required production related information by its unique IO card, PLC, ERP which system factory already has. Collected data procures to clearly identify the reasons of production stops, time loss, etc.

Oil & Gas Industry

In oil & gas production industry, production process needs continuous in very sophisticated manufacturing management. MSF gives production management automation and information solution with computer…

Chemical Industry

The chemicals industry needs a high degree of automation, and most plants is monitored standard variables such as temperature, flows, tank levels, and pressures to derive optimal plant working conditions.

Steel Die Casting Industry

HVAC Industry

For HVAC industry MSF can also be available their needs. Most air conditioners are processed starting out as raw material, in the form of structural steel shapes and sheet steel. As the sheet metal is processed into fabrication…

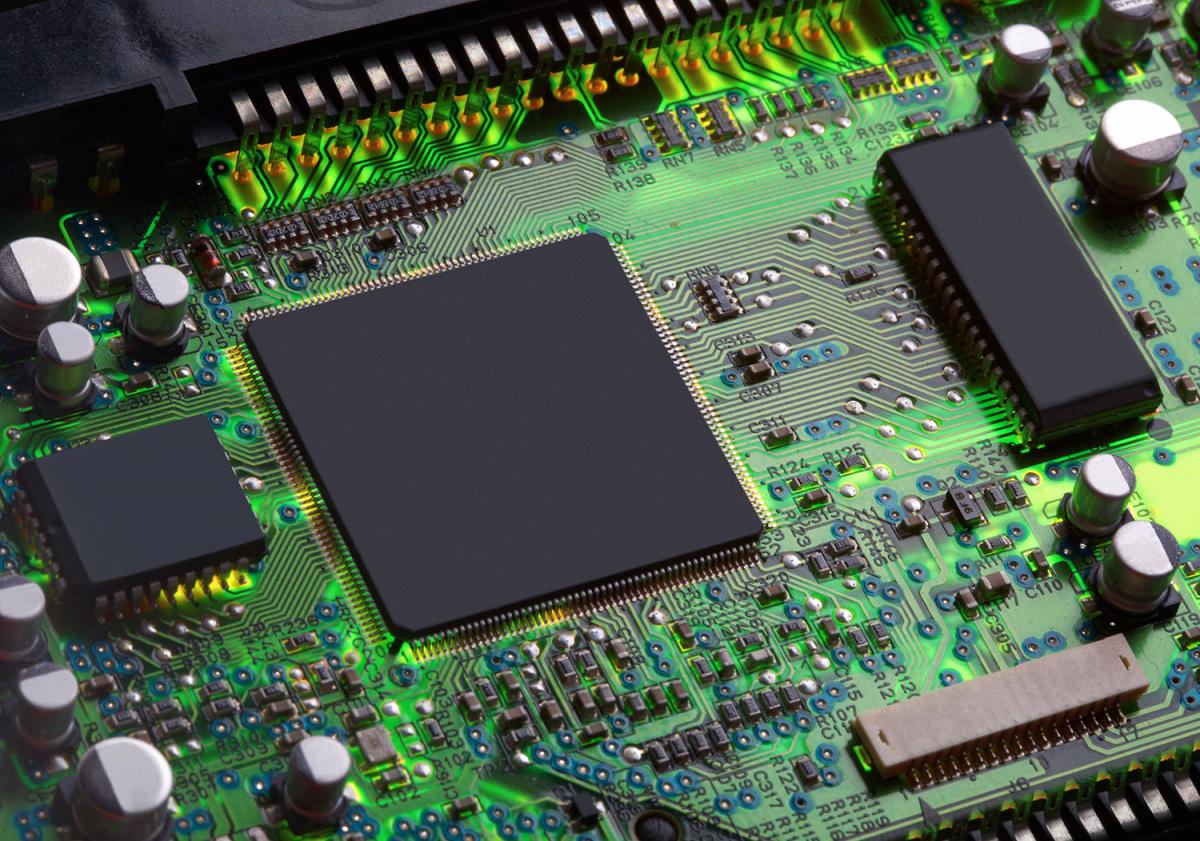

Flexible Printed Circuits

Packaging Industry

For packaging companies, the entire automation and supply chain processes are very important in production with utilizing advanced technology systems in production areas, assembly lines, monitoring and control, instrumentation, data management and processing, and machineries.

Food Industry

Food industry produces every product based on the mainly customer demand to be in bit forward in competition in their producers today.

MSF gives the ways to improve productivity in terms of maintaining safety, using sustainable packaging…

Solar Panel Industry

MSF MES system is available for solar panel production process. All source of production data necessary to customize MSF MES system like PLC, ERP are collected from digital factory tools. Using unique MSF smart IO cart, MSF retrieves and process all real time machine…

Kitchen Equipment Industry

MSF has holistic view of manufacturing operations which is gathered data from several different enterprise sources. Advanced MSF analytics are used to fully understand the performance of the manufacturing processes, quality of products and supply chain optimization.

Glass Factory Industry

Steklarna Hrastnik 1860

MSF is part of the consortium of the CEDIT.SI project by glass factory Hrastnik.

For them we will develop customizable Advanced planning and Labor scheduling for increasing productivity in glass factories, and making digital twin.